Ejector Pin Suppliers,Traders,Dealers in Pune, Maharashtra

Ejector Pin Suppliers in Pune|Ejector Pin Dealers in Pune|Ejector Pin Traders in Pune|Ejector Pin in Maharashtra

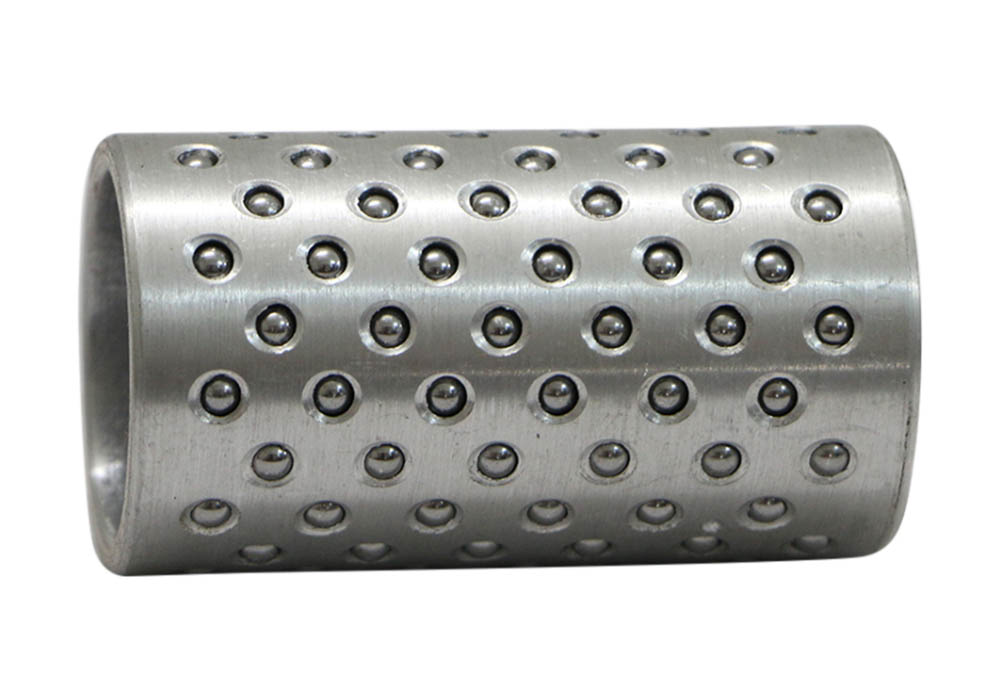

We at Sujoy Enterprises are prominent suppliers, dealers and Traders of an Ejector Pins in Pune, Maharashtra. These are an integral part of the mold ejection system that determines the final product result in the injection molding process.

An ejector pin is located on his B-side half of the mold, from which it pushes the part out of the mold. Ejector shape markings are typically embossed as indentations in the finished product.

Ejector Pin Types

The ejector pin market offers three popular types of pins: through-hard pins, nitride H13 pins, and the recently introduced black Ejector Pins. Each variety possesses distinct characteristics and is designed to excel in specific environments. Each type has its own unique characteristics and is designed for specific applications.

Through Hard Pins:

Through-hard pins are designed with consistent hardness throughout their diameter. This feature allows them to have a longer lifespan when used in working temperatures below 200°C. These pins are particularly suitable for plastic injection moulds.

Nitride H13 Pins:

Nitride H13 pins are a better choice when working temperatures exceed 200°C. These pins have a surface hardness of HRC 65 to 70, which significantly increases their durability in high-temperature environments. They are commonly used in die casting applications.

Black Ejector Pins:

For working temperatures exceeding 600°C, nitride H13 pins are not suitable. To address this limitation, black ejector pins have been developed. These pins are coated with a special black surface treatment that enables them to withstand temperatures up to 1,000°C. Additionally, the black coating provides enhanced self-lubrication properties, making these pins an excellent choice for automobile injection moulding. While suitable for most working temperatures, it's important to note that black ejector pins have a higher cost compared to other options.

Ejector Pin Suppliers, Dealers and Traders in Pune – Size & Material

Stainless Steel Ejector Pin Size 150mm

| Size | 150 mm |

| Material | Stainless Steel |

| Material Grade | SS316 |

| Finish | Polished |

| Head Shape | Round |

Ejector Pin: Box Type Size: 40 mm - 400 mm

| Size | 40 mm - 400 mm |

| Material | Stainless Steel |

| Material Grade | EN -31 |

| Packaging Type | Box |

| Finish | Harden |

5.5mm x 100mm Ejector Pin Type: Box

| Size | 5.5mmx100mm |

| Material | SS |

| Packaging Type | Box |

| Finishing | Polished |

| Material | Stainless Steel |

| Material Grade | 304 |

| Hardness | 70 HRC |

| Country of Origin | Made in India |

| Tensile Strength | 350 MPa |

| Corrosion Resistance | Yes |

| Thickness | 3 mm |

Ejector Pin Suppliers, Dealers and Traders in Pune - Price & Cost

Explore a comprehensive selection of high-quality Ejector Pin suppliers, dealers and traders across India. With over 100 different products to choose from, you can find the perfect ejector pin to meet your specific requirements. Our wide range of ejector pins includes options such as HDS ejector pins, stepped ejector pins, mold ejector pins, and more, ensuring that you can find the ideal solution for your injection molding needs.

In terms of pricing, ejector pin suppliers in Pune are available at competitive prices, ranging from approx. 1 to 10000 INR. The minimum order requirements vary from 1 to 5000, making it convenient for businesses of all sizes to access the ejector pins they need.

Hardened Pins

Size: 2mm To 50mm

Approx ₹1.30/Piece

Hardened Pins

more than 100 mm

Approx ₹9/Piece

H13 Hotwork Die Steel

Type A Din Ejector Pin

Approx ₹44/Piece

Black MS

Ejector Pin

Approx ₹45/Piece

Ejector Pin Advantages

The use of Ejector Pins offers several advantages in manufacturing processes, particularly in injection molding and die casting. Some of the key advantages of ejector pins include:

Efficient Part Ejection: Ejector pins allow for quick and efficient removal of finished parts from molds or dies. They provide the necessary force to push or eject the product out of the mold cavity, enabling smooth and continuous production cycles.

Enhanced Productivity: By expediting the ejection process, ejector pins contribute to increased productivity. They minimize the time required for part removal, allowing for faster cycle times and higher production volumes.

Improved Part Quality: Ejector pin suppliers in pune helps to ensure the integrity and quality of finished parts. By facilitating their easy removal from molds or dies, the risk of part distortion, damage, or deformation during ejection is reduced. This results in consistent and high-quality parts.

Mold Protection: Ejector pins play a role in protecting the molds or die themselves. By exerting force on the finished part, they help prevent the part from sticking to or damaging the mold cavity during ejection. This helps extend the lifespan of the mold or die, reducing maintenance and replacement costs.

Design Flexibility: The use of ejector pin suppliers in pune provides design flexibility in terms of part geometry and complexity. They allow for the production of intricate parts with undercuts or complex shapes by enabling their successful ejection from the mold.

Cost-Effectiveness: Ejector pins are relatively simple and cost-effective components compared to other mold or die elements. Their use helps streamline production processes and minimize the need for manual intervention, leading to cost savings and improved efficiency.

Tags

Ejector Pin Suppliers in Pune | Ejector pin Dealers in Pune | Ejector pin Traders in Pune

FAQs

-

Q1. What is Ejector Pin?

An ejector pin is a specialized tool used in various manufacturing processes, particularly in injection moulding and die casting. It is designed to facilitate the removal of a finished part or product from a mold or die.

-

Q2. What is the Hardness of Ejector Pins?

The ejector pins have a surface hardness of 65-74 Rc and core hardness of 40-45 Rc. Pin diameters that are 3/32” or larger are etched for easy identification.

-

Q3. What Material is used for Ejector Pins?

Straight ejector pins, manufactured from premium die steel materials such as EN-31, H-13 (SKD 61), or HSS (M2), play a vital role in the production of molded goods. To ensure high precision and consistent surface quality, the heads of these ejector pins undergo hot forging and stress relieving processes.

-

Q4. How Ejector Pins Helps in Injection Molding

Ejector pins play a crucial role in the injection molding process by facilitating the removal of finished parts from the mold. When manufacturing plastic parts through injection molding, molten plastic is injected into a metal mold. Once the plastic has cooled and solidified inside the mold, the two halves of the metal mold, typically referred to as the A-side and B-side, are separated.

-

Q5. How much temperature resistance Capacity for ejector pins?

Different types of ejector pins offer varying levels of temperature resistance to suit different applications and molding processes.

Through-hardened ejector pins up to approximately 200 degrees Celsius.

Nitride H13 ejector pins can withstand temperatures exceeding 200 degrees Celsius with hardness of 65 to 70 HRC

black ejector pins can withstand temperatures up to around 600 degrees Celsius

-

Q6. What is the purpose of use Ejector Pins?

An ejector pin uses a crucial purpose in the injection molding process by facilitating the effortless removal of the formed material from the mold. Its primary function is to push or eject the solidified plastic, which has taken on the shape of the mold cavity, making it easy to extract the finished part.

What We Do?

We Supply All This Products